Where to Buy Electrolytic Aluminum Waste Slag Grinding Mill Equipment?

Where to Buy Electrolytic Aluminum Waste Slag Grinding Mill Equipment?

If you’re in the market for grinding mill equipment to process electrolytic aluminum waste slag, you’ve come to the right place. This matierial, a byproduct of aluminum production, requires specialized machinery to be effectively ground into a fine, reusable powder. The choice of equipment is critical for efficiency, cost-effectiveness, and environmental compliance.

Key Considerations for Slag Grinding

Electrolytic aluminum slag is abrasive and can be variable in composition. A suitable mill must offer robust construction, high grinding efficiency, and the ability to produce a consistently fine powder. Energy consumption is a major operational cost, so an energy-efficient design is paramount. Furthermore, integrated dust collection is not a luxury but a necessity to meet strict environmental regulations and maintain a safe workplace.

Top Equipment Recommendation: MW Ultrafine Grinding Mill

For operations prioritizing ultra-fine powder production with exceptional environmental controls, our MW Ultrafine Grinding Mill is an outstanding choice. This machine is engineered for customers who need to make ultra-fine powder from various materials, including abrasive industrial wastes like aluminum slag.

Here’s why it excels for this application:

- Higher Yielding, Lower Energy Consumption: Its newly designed grinding curves enhance efficiency. Production capacity is 40% higher than jet mills and yield is twice as large as ball mills, while system energy consumption is only 30% of a jet mill. This translates directly to lower operating costs per ton of processed slag.

- Adjustable Fineness (325-2500 meshes): Its advanced German cage-type powder selector allows for precise control over the final product’s fineness, crucial for finding new markets for your processed slag.

- Eco-Friendly Operation: It comes equipped with an efficient pulse dust collector and muffler, ensuring no dust pollution and reduced noise during operation. This makes the entire production process compliant with national environmental protection standards.

- Reliable Design: With no rolling bearings or screws in the grinding chamber, you avoid common failure points. External lubrication allows for 24/7 operation without shutdowns for maintenance.

With an input size of 0-20 mm and a capacity range of 0.5-25 tph, the MW series offers flexibility for various production scales.

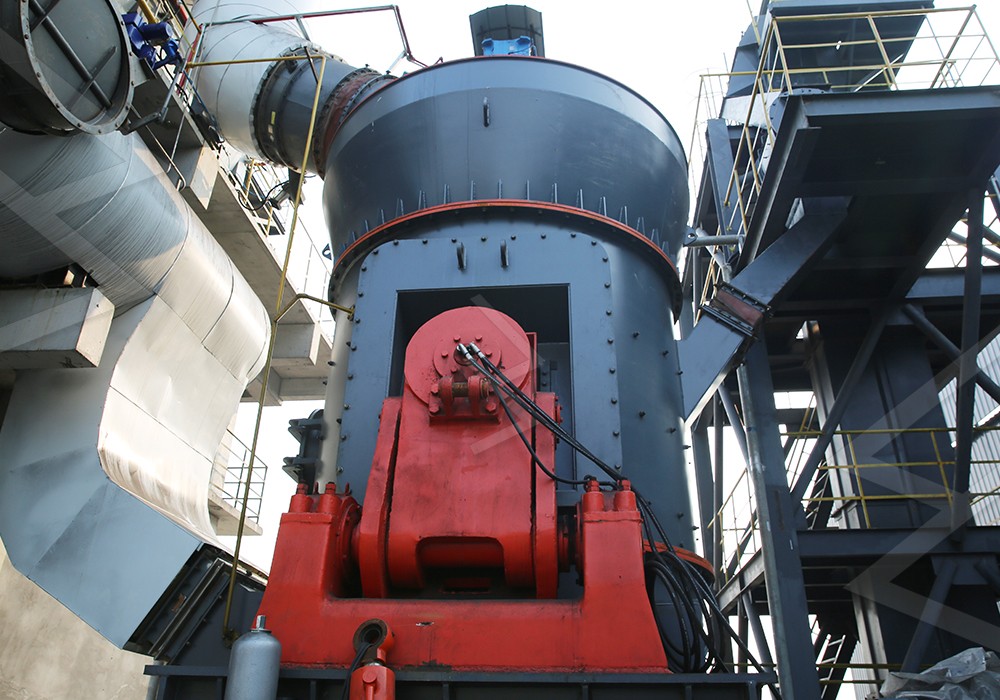

Another Strong Contender: LM Vertical Slag Mill

For larger-scale operations focused specifically on slag, our LM Vertical Slag Mill is a purpose-built solution. It integrates drying, grinding, powder selection, and conveying into a single, compact unit.

Its advantages include:

- Dedicated design for industrial waste like steel and aluminum slag.

- Significantly reduced energy consumption (30-40% less than ball mill systems).

- A small footprint, reducing the required factory space by about 50%.

- Integrated grinding and powder selection simplifies the process flow and reduces investment cost.

Why Choose Our Equipment?

Beyond the machines themselves, we provide comprehensive support. We take responsibility for every machine we produce, offering technical services and a sufficient supply of original spare parts to ensure worry-free, continuous operation. Our digitalized processing ensures high precision in manufacturing, especially for core components, guaranteeing reliability and longevity.

Final Thoughts

Choosing the right grinding mill for electrolytic aluminum waste slag is a significant decision that impacts your productivity, operational costs, and environmental footprint. The MW Ultrafine Grinding Mill, with its focus on ultra-fine powder and environmental protection, and the LM Vertical Slag Mill, with its integrated design for high-volume slag processing, represent two of the best options on the market.

For a detailed quotation and to discuss which model best fits your specific project requirements, contact our technical sales team today. Let us help you transform your waste slag into a valuable resource.