Slag Vertical Mill: Output Capacity and Price Analysis

Slag Vertical Mill: Output Capacity and Price Analysis

In the world of industrial milling, slag processing presents unique challenges. Traditional ball mills, while reliable, often struggle with efficiency, energy consumption, and the abrasive nature of slag. Vertical roller mills (VRMs) have emerged as a superior solution, offering a compelling combination of high output, lower operational costs, and a smaller physical footprint. This analysis delves into the key factors influencing the output capacity and pricing of slag vertical mills, providing insights for potential investors and plant operators.

Understanding Capacity Drivers

The output capacity of a slag vertical mill is not a fixed number; it’s influenced by several interconnected factors. The primary determinants are the grindability of the slag (its Hardgrove grindability index), the desired fineness of the final product, and the moisture content of the feed material. A harder slag or a requirement for ultra-fine powder will naturally reduce the hourly throughput. Furthermore, mills equipped with advanced drying capabilities can handle higher moisture content without sacrificing grinding efficiency, directly impacting overall system capacity.

The Economic Advantage: Operational Costs

While the initial capital investment for a vertical mill might be higher than a traditional ball mill system, the long-term operational savings are significant. Vertical mills are renowned for their energy efficiency, typically consuming 30% to 40% less power than a ball mill producing the same product. This is achieved through their principle of bed comminution rather than impact and attrition. Additionally, their integrated drying system eliminates the need for a separate dryer, further reducing energy and infrastructure costs. Wear part consumption is also generally lower due to the reduced metal-to-metal contact.

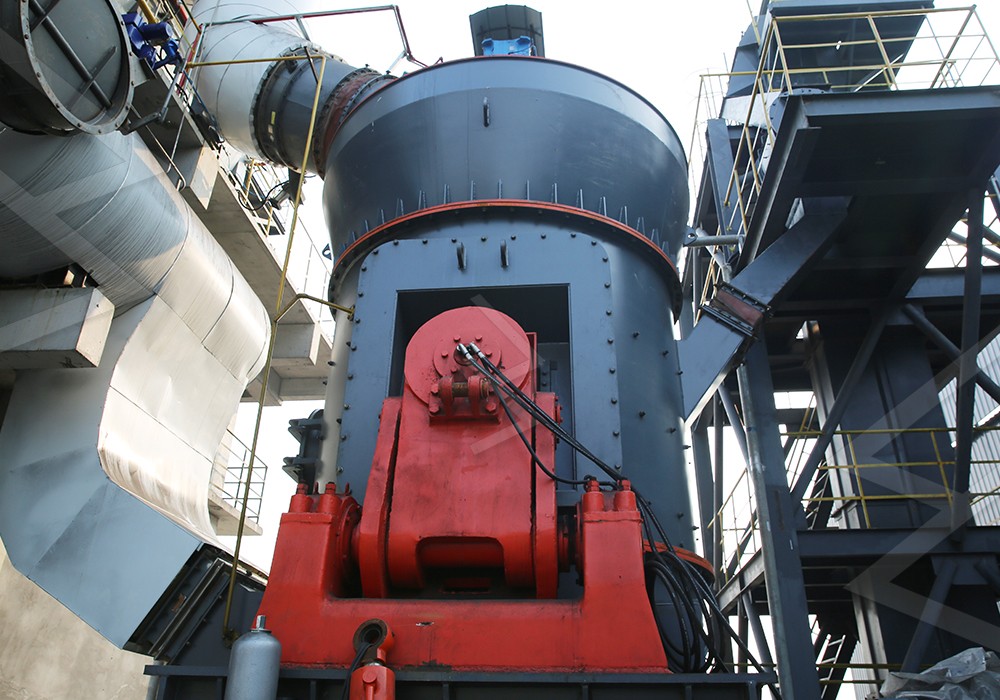

Product Spotlight: LM Vertical Slag Mill

For operations focused specifically on industrial waste like slag, a specialized machine is paramount. Our LM Vertical Slag Mill is engineered precisely for this demanding application. It integrates drying, grinding, powder selection, and conveying into a single, compact unit. With a capacity range of 7-100 T/H and the ability to handle input sizes up to 65mm, it’s built for scale. Its core advantage lies in its energy consumption, which is 30% ~ 40% of a comparable ball milling system, translating to massive utility savings year over year. The unique grinding device achieves the integration of grinding and powder selection, ensuring a uniform and high-quality final product perfect for cement and concrete production.

Considering the LUM Ultrafine Vertical Alternative

For projects requiring extremely fine slag powders or processing of other non-metallic minerals, the LUM Ultrafine Vertical Grinding Mill presents a formidable option. While its input size is smaller (0-10mm) and capacity range is 5-18 TPH, it excels in precision. It incorporates the latest roller technology and German powder separating technology to produce superfine dry powder. A key feature is its double position-limiting technology, which guarantees operational stability by preventing destructive impacts between the roller and millstone, a critical factor for continuous 24/7 operation.

Pricing Structure

The price of a slag vertical mill is not a one-size-fits-all figure. It scales with the required capacity, the level of automation, and the choice of ancillary equipment (e.g., specific dust collection or feeding systems). A smaller capacity mill like the LUM series will have a different price point than a high-tonnage LM Vertical Slag Mill. Furthermore, opting for advanced digital control systems and premium wear-resistant materials for grinding rollers and tables will increase the initial investment but pay dividends in reduced downtime and maintenance costs.

Conclusion

Selecting the right slag vertical mill is a strategic decision that balances initial capital expenditure with long-term operational efficiency and output quality. The move towards vertical roller technology is a clear trend driven by undeniable economic and environmental benefits. Whether your priority is massive throughput with the LM Vertical Slag Mill or ultra-fine precision with the LUM Ultrafine Vertical Grinding Mill, understanding the relationship between feed material, desired product, capacity, and total cost of ownership is key to a successful investment.