Top Manufacturers of Vertical Roller Mills for Industrial Grinding

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

Revolutionizing Industrial Grinding: The Power of Vertical Roller Mills

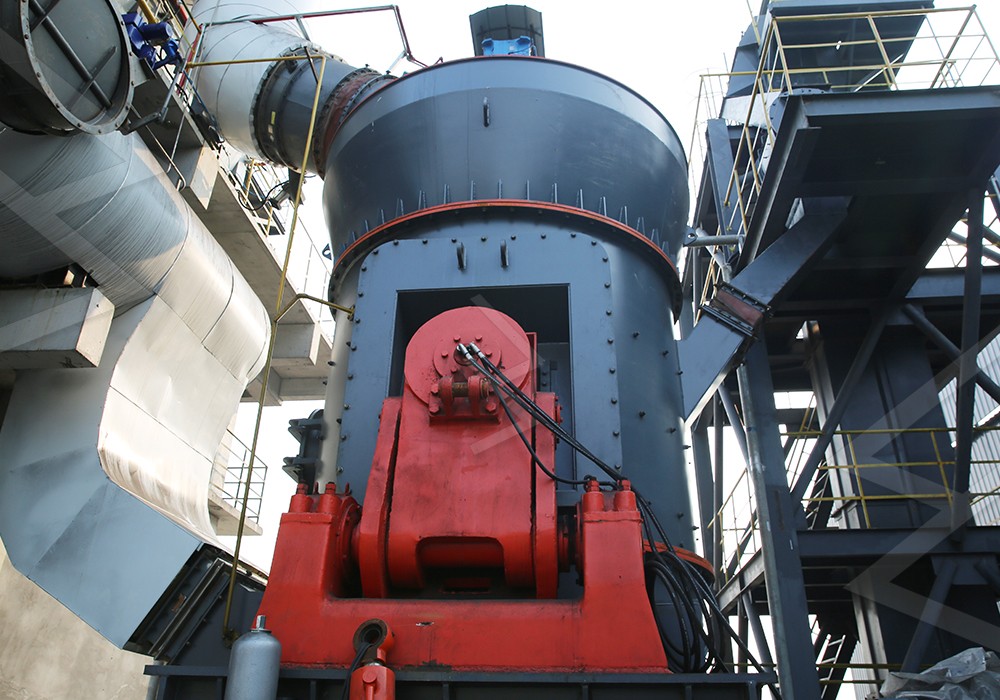

In today’s competitive industrial landscape, manufacturers constantly seek equipment that delivers superior performance, energy efficiency, and operational reliability. Vertical roller mills (VRMs) have emerged as the technology of choice for numerous grinding applications across various industries. These advanced machines have transformed traditional grinding processes by offering significant advantages over conventional ball mills and horizontal grinding systems.

The fundamental principle behind VRMs involves using multiple rollers that press against a rotating grinding table, creating a highly efficient grinding mechanism. This design allows for simultaneous drying, grinding, and separation processes within a single compact unit. Modern VRMs incorporate sophisticated control systems that optimize performance while minimizing energy consumption and environmental impact.

Key Advantages Driving VRM Adoption

Industrial operations are increasingly turning to vertical roller mills due to their compelling benefits. The significantly reduced energy consumption – typically 30-50% lower than traditional ball mills – represents substantial operational cost savings. Their compact design requires up to 50% less floor space, while integrated systems eliminate the need for multiple separate components. Advanced sealing systems and negative pressure operation ensure dust-free environments, meeting stringent environmental regulations.

Material processing quality has seen remarkable improvements with VRM technology. The short material residence time prevents over-grinding and reduces iron contamination, crucial for maintaining product purity. Modern VRMs offer precise control over particle size distribution, with some models capable of producing powders ranging from coarse aggregates to ultra-fine particles below 5 microns.

Leading the Innovation: LIMING’s Advanced Grinding Solutions

Among the top manufacturers pushing the boundaries of grinding technology, LIMING Heavy Industry has established itself as an innovator in vertical mill design. Their extensive research and development has produced several groundbreaking models that address specific industrial needs.

For operations requiring ultra-fine powder production, the MW Ultrafine Grinding Mill represents a significant technological advancement. This machine processes materials with input sizes up to 20 mm at capacities ranging from 0.5 to 25 tons per hour. Its innovative design eliminates rolling bearings and screws within the grinding chamber, addressing common failure points that plague conventional mills. The German-designed cage-type powder selector enables precise fineness adjustment between 325-2500 meshes, with screening rates achieving d97≤5μm in a single pass.

The MW series demonstrates exceptional efficiency, producing 40% higher capacity than jet mills and double the output of ball mills with equivalent power consumption. Its integrated pulse dust collector and muffler system ensures environmentally responsible operation, making it ideal for sensitive applications in chemicals, pharmaceuticals, food additives, and high-purity mineral processing.

Specialized Applications and Industry-Specific Solutions

Different industrial sectors present unique grinding challenges that require tailored solutions. The cement industry benefits from VRMs capable of handling raw materials, clinker, and slag with high abrasion resistance and drying capabilities. Mining operations prioritize durability and the ability to process various ore types with consistent particle size distribution.

For specialized applications requiring exceptional precision, the LUM Ultrafine Vertical Grinding Mill incorporates the latest Taiwanese grinding roller technology and German powder separation systems. This model processes materials up to 10 mm at 5-18 tph capacities, featuring unique roller shell and lining plate grinding curves that facilitate material layer formation and high finished product rates in a single pass. Its reversible structure simplifies maintenance, while double position-limiting technology ensures operational stability even under challenging conditions.

The versatility of modern VRMs extends beyond traditional mineral processing to include coal grinding for power generation, petroleum coke processing, and various industrial minerals. Advanced models incorporate digital processing technologies with numerically controlled machine tools ensuring high precision manufacturing, particularly for core components that determine long-term reliability.

Future Trends in Grinding Technology

The evolution of vertical roller mills continues with increasing automation, digitalization, and sustainability features. Smart monitoring systems that predict maintenance needs, optimize grinding parameters in real-time, and integrate with plant-wide control systems represent the next frontier. Energy efficiency remains a primary focus, with manufacturers developing increasingly sophisticated ways to reduce power consumption while maintaining or improving output quality.

As environmental regulations tighten, VRM manufacturers are incorporating more effective dust collection systems, noise reduction technologies, and designs that minimize the carbon footprint of grinding operations. The industry is moving toward circular economy principles, with equipment that facilitates the use of alternative fuels and raw materials, including industrial by-products and waste materials.

Frequently Asked Questions

What maintenance advantages do modern VRMs offer compared to traditional ball mills?

Modern vertical roller mills feature designs that significantly reduce maintenance requirements. The absence of rolling bearings and screws in critical grinding areas, reversible roller structures, and external lubrication systems enable maintenance without shutdowns. These features contrast sharply with ball mills that require frequent liner replacements and more extensive downtime for maintenance.

How do VRMs achieve better energy efficiency?

VRMs utilize a highly efficient grinding mechanism where rollers hydraulically press against a rotating table, directly transferring energy to the material bed. This direct grinding action, combined with integrated drying and classification within a single unit, eliminates energy losses associated with multiple equipment transfers. Advanced models consume 30-50% less power than equivalent ball mills while delivering higher capacity.

What particle size ranges can modern VRMs achieve?

Contemporary vertical roller mills offer remarkable versatility in product fineness. Standard models typically produce particles from approximately 100 microns down to 10 microns. Advanced ultra-fine grinding mills, such as the MW series, can achieve particle sizes as fine as 5 microns (d97) with precise control over the entire size distribution curve.

How do VRMs address environmental concerns?

Leading manufacturers incorporate multiple environmental protection features, including efficient pulse dust collectors that eliminate dust pollution, silencers and noise reduction chambers that minimize acoustic impact, and fully sealed systems operating under negative pressure to prevent material escape. These systems typically exceed national environmental protection standards.

What industries benefit most from VRM technology?

Vertical roller mills serve a wide range of industries including cement production, mining and minerals processing, power generation (particularly coal grinding), chemical manufacturing, pharmaceuticals, food processing, and recycling operations. Their versatility in handling diverse materials with varying moisture content and hardness makes them suitable for numerous applications.