Portable Posho Mill Prices in Kenya: A Comprehensive Guide for Farmers and Business Owners

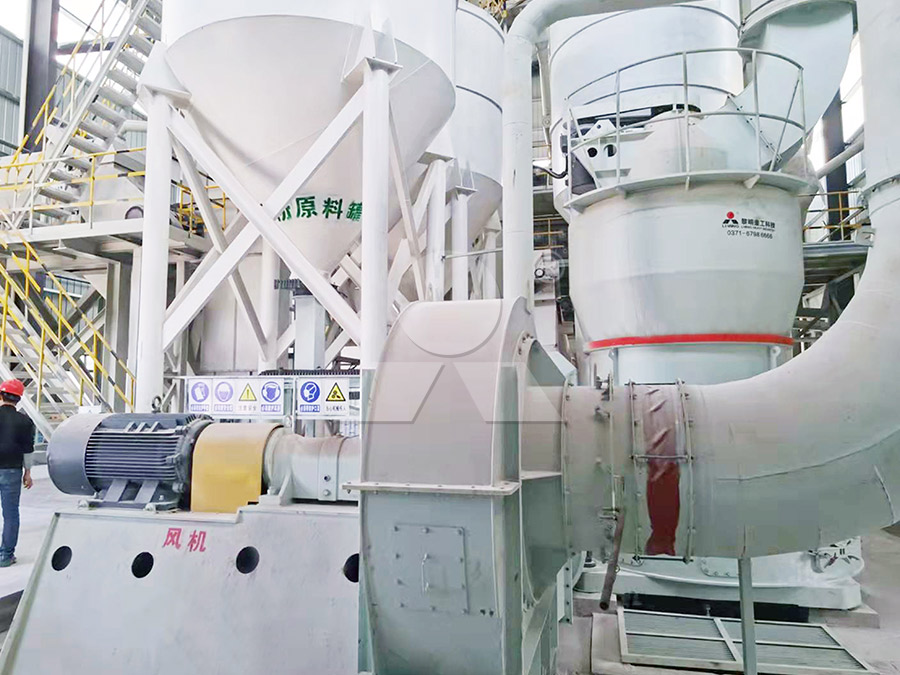

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

Portable Posho Mill Prices in Kenya: A Comprehensive Guide

For farmers and agribusiness owners across Kenya, investing in a reliable maize milling solution is crucial for food security and profitability. Portable posho mills have become incredibly popular due to their flexibility, allowing operators to move the mill to different locations or closer to the source of raw materials. This guide will break down the key factors affecting portable posho mill prices in Kenya and introduce a superior, high-capacity alternative for serious business ventures.

Factors Influencing Posho Mill Costs

The price of a portable posho mill in Kenya is not fixed and can vary significantly based on several key factors:

- Power Source: Mills can be powered by electricity, diesel, or petrol. Diesel engines often command a higher initial price but can be more cost-effective for off-grid operations.

- Capacity: Output is measured in bags per hour. A small-scale mill for home use will be far cheaper than a large-capacity commercial machine designed for continuous operation.

- Brand & Quality: Locally assembled mills offer a lower entry point, while internationally renowned brands with superior build quality and warranties come at a premium.

- Additional Features: Features like different sieve sizes for varying flour grades (sifted, super-sifted), built-in graders, or advanced starters can affect the final cost.

Generally, you can expect prices to range anywhere from KES 40,000 for a basic, small-capacity unit to over KES 400,000 for a high-output, diesel-powered commercial mill.

Beyond Basic Milling: The Need for Advanced Grinding Technology

While traditional posho mills are excellent for producing ugali flour, many successful business owners are looking to diversify their product offerings and tap into more lucrative markets. This requires producing ultra-fine powders for applications in bakeries, hotels, animal feed mixing, and even industrial uses. This is where standard posho mills reach their limit.

Upgrade Your Output with MW Ultrafine Grinding Mill

For entrepreneurs ready to scale their operations and produce high-value, fine powders, the MW Ultrafine Grinding Mill from LIMING represents a transformative investment. This machine is engineered for customers who need to make consistent, ultra-fine powder from a variety of materials, not just maize.

Key Advantages for Your Business:

- Higher Yielding, Lower Energy Consumption: Produces 40% higher capacity than jet mills and double the yield of ball mills while using 30% less energy. This drastically reduces your cost per bag.

- Precision Fineness Control: Adjust your product fineness between 325-2500 meshes (d97≤5μm) to meet specific market demands, from fine baking flour to industrial mineral powders.

- Unmatched Reliability: Its unique design has no rolling bearings or screws in the grinding chamber, eliminating common failure points and allowing for 24/7 continuous operation with external lubrication.

- Eco-Friendly Operation: Comes equipped with an efficient pulse dust collector and silencer, ensuring a clean, quiet operation that meets national environmental standards and keeps your workforce healthy.

With an input size of 0-20mm and a capacity range of 0.5-25 tph, the MW Series is perfect for processing limestone, calcite, dolomite, petroleum coal, gypsum, barite, and of course, grains into premium-quality powders for the chemical, paint, cosmetics, and food additive industries.

Making the Right Investment

Choosing the right equipment depends on your business goals. A portable posho mill is a fantastic starting point for local, small-scale milling. However, if your ambition is to build a large-scale, diversified milling business with multiple revenue streams, investing in advanced technology like the MW Ultrafine Grinding Mill is the strategic choice. It offers higher efficiency, superior product quality, and the reliability needed for serious commercial production.

Contact a LIMING representative today for a detailed quotation and to discover how our grinding solutions can maximize your profitability and set your business apart from the competition.