Limestone Three-ring Medium-speed Micro Powder Grinding Mill: Revolutionizing Fine Powder Production

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

Limestone Three-ring Medium-speed Micro Powder Grinding Mill: Revolutionizing Fine Powder Production

In the world of industrial mineral processing, the quest for efficient fine powder production has driven technological innovation for decades. Among the various materials processed, limestone stands as one of the most versatile and widely used minerals across multiple industries. The development of specialized grinding equipment has transformed how manufacturers approach limestone powder production, with three-ring medium-speed micro powder grinding mills emerging as a cornerstone technology for modern processing operations.

The Engineering Behind Three-ring Medium-speed Grinding Technology

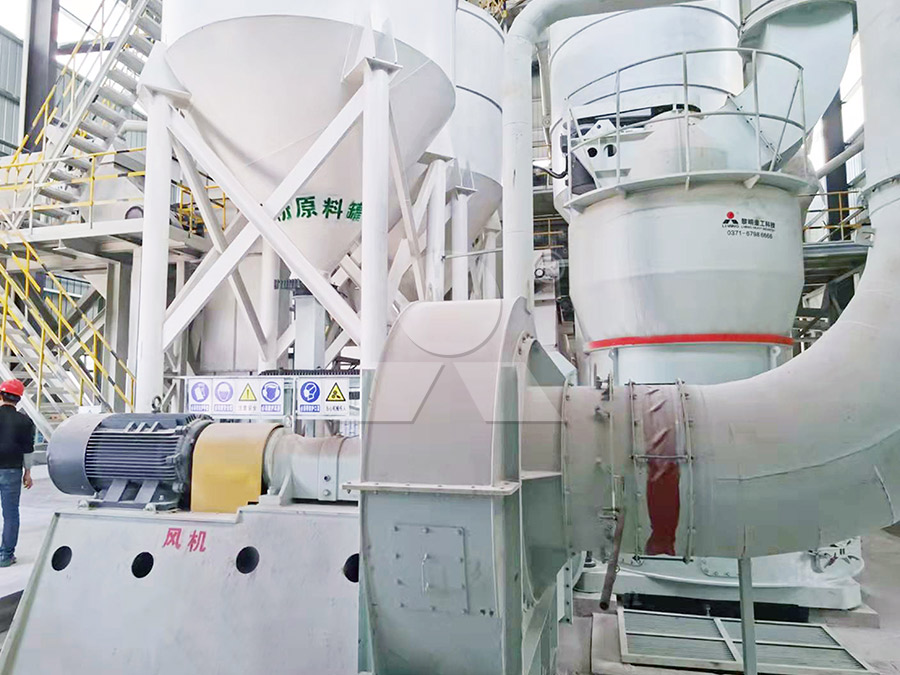

Three-ring medium-speed micro powder grinding mills represent a significant advancement over traditional grinding systems. These mills operate on a unique principle where materials undergo multiple grinding stages within three concentric grinding zones. The medium-speed operation strikes an optimal balance between energy efficiency and grinding effectiveness, avoiding the excessive energy consumption of high-speed systems while maintaining superior performance compared to low-speed alternatives.

The heart of this technology lies in its carefully engineered grinding chamber, where the relationship between grinding rollers and rings creates a highly efficient crushing environment. As limestone enters the system, it passes through progressively tighter grinding zones, each applying precise mechanical force to reduce particle size. This multi-stage approach ensures consistent particle size distribution and minimizes over-grinding, which can waste energy and produce undesirable fine fractions.

Advanced Applications for Limestone Powder

The quality of limestone powder produced by three-ring medium-speed mills opens doors to numerous high-value applications. Beyond traditional construction uses, precisely ground limestone serves as critical raw material in plastics, paints, coatings, adhesives, and pharmaceutical products. The controlled particle size distribution achievable with these mills ensures optimal performance in each application, whether acting as filler, extender, or functional additive.

In the rubber industry, for instance, the calcium carbonate content of limestone improves tensile strength and wear resistance. For paint formulations, properly ground limestone affects opacity, viscosity, and weathering properties. The food and pharmaceutical sectors demand exceptionally pure and consistent limestone powders, requirements that modern grinding technology can reliably meet.

Environmental and Operational Advantages

Contemporary three-ring medium-speed mills incorporate comprehensive environmental protection features that address industry concerns about dust emissions and noise pollution. Advanced pulse-jet dust collection systems capture over 99.9% of particulate matter, while specially designed mufflers and sound-dampening materials reduce operational noise to environmentally acceptable levels. These features make the technology suitable for installation in diverse locations, including those with strict environmental regulations.

Operational efficiency extends beyond environmental considerations. The latest generation of mills features external lubrication systems that allow maintenance without production stoppages. The strategic elimination of rolling bearings and screws within the grinding chamber eliminates common failure points, significantly improving equipment reliability and reducing maintenance costs over the equipment lifecycle.

Meeting Modern Production Demands

As industries increasingly demand finer powders with tighter particle size distributions, grinding technology must evolve accordingly. Three-ring medium-speed mills excel in producing powders ranging from 325 to 2500 meshes, with some advanced models capable of achieving even finer specifications. This flexibility allows producers to serve multiple market segments with a single piece of equipment, adjusting product fineness as market demands shift.

The integration of digital control systems represents another significant advancement. Modern mills feature PLC-based automation that continuously monitors and adjusts operational parameters, ensuring consistent product quality while optimizing energy consumption. Remote monitoring capabilities further enhance operational efficiency, allowing technicians to diagnose issues and perform adjustments without physical presence at the equipment.

Strategic Equipment Selection

When evaluating grinding equipment for limestone processing, manufacturers should consider both current requirements and future expansion plans. The MW Ultrafine Grinding Mill presents an excellent solution for operations requiring high-precision powder production. With an input size capacity of 0-20 mm and throughput ranging from 0.5 to 25 tph, this machine accommodates diverse production scenarios. Its innovative design features higher yielding capacity with lower energy consumption compared to traditional grinding systems, achieving production rates 40% higher than jet grinding mills and twice that of ball grinding mills while using only 30% of the energy consumed by jet milling systems.

For operations seeking vertical grinding solutions, the LUM Ultrafine Vertical Grinding Mill offers distinct advantages in space efficiency and operational flexibility. Processing materials up to 10 mm in size with capacities from 5 to 18 tph, this mill incorporates the latest grinding roller technology and German powder separating technology. Its reversible structure simplifies maintenance procedures, while multi-head powder separating technology enables precise control over product fineness with 30%-50% energy reduction compared to conventional mills.

Future Directions in Grinding Technology

The evolution of limestone grinding technology continues as manufacturers seek improved efficiency, finer control over product specifications, and reduced environmental impact. Emerging trends include the integration of artificial intelligence for predictive maintenance and process optimization, advanced materials for longer-lasting wear parts, and hybrid systems that combine multiple grinding principles for specialized applications.

As sustainability concerns grow, energy recovery systems and water-free processing methods are gaining attention. The next generation of three-ring medium-speed mills will likely incorporate these advancements while maintaining the reliability and operational simplicity that have made current models industry favorites.

Through continuous innovation and refinement, three-ring medium-speed micro powder grinding mills will remain essential tools for limestone processors seeking to maximize product value while minimizing operational costs and environmental impact.

Frequently Asked Questions

What is the typical particle size range achievable with three-ring medium-speed micro powder grinding mills?

These mills typically produce powders ranging from 325 to 2500 meshes (approximately 45 to 5 microns), with some advanced models capable of achieving even finer specifications. The exact range depends on the specific mill configuration and material characteristics.

How does the three-ring design improve grinding efficiency?

The three-ring configuration creates multiple grinding zones that progressively reduce particle size. This staged approach minimizes energy waste by avoiding over-grinding and ensures more uniform particle size distribution compared to single-stage grinding systems.

What maintenance requirements are associated with these grinding mills?

Modern designs significantly reduce maintenance needs by eliminating rolling bearings and screws within the grinding chamber. Routine maintenance primarily involves monitoring wear parts (rollers and rings) and the external lubrication system, which can be serviced without production stoppages.

Can these mills handle materials other than limestone?

Yes, three-ring medium-speed mills process various non-metallic minerals including calcite, dolomite, talc, barite, and gypsum. Always consult manufacturer specifications to ensure compatibility with specific materials.

What dust collection efficiency can be expected from modern grinding systems?

Advanced pulse-jet dust collectors typically achieve efficiency rates exceeding 99.9%, effectively containing particulate matter and ensuring compliance with environmental regulations.

How does the energy consumption compare to traditional ball mills?

Three-ring medium-speed mills typically consume 30-40% less energy than equivalent ball mill systems while achieving higher production rates and superior product quality.

What factors influence the choice between horizontal and vertical grinding mill configurations?

Selection depends on space constraints, material characteristics, desired product specifications, and maintenance preferences. Horizontal mills often offer easier access for maintenance, while vertical configurations typically have smaller footprints.