How to Produce Silica Powder Using a Ball Mill: A Comprehensive Guide

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

How to Produce Silica Powder Using a Ball Mill: A Comprehensive Guide

Silica powder, a fundamental material in countless industries from ceramics to electronics, requires precise and efficient production methods. While the traditional ball mill has long been a workhorse for size reduction, modern operations demand higher yields, finer particle sizes, and greater energy efficiency. This guide walks you through the ball milling process for silica and introduces a superior alternative for ultra-fine powder production.

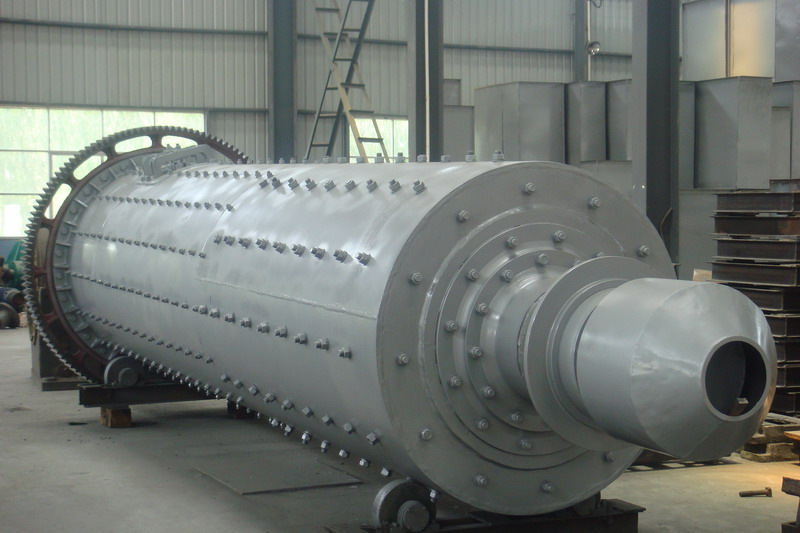

The Ball Milling Process for Silica

The classic ball mill operates on a relatively simple principle. It is a horizontal rotating cylinder, or shell, partially filled with grinding media—typically high-density ceramic or steel balls. The raw silica feed, crushed to a size below 25mm, is introduced into this shell. As the mill rotates, the balls are lifted and then cascade down, impacting the silica particles and crushing them through a combination of impact and attrition forces.

Key factors influencing the final product in a ball mill include:

- Rotation Speed: Optimal speed is critical. Too slow, and the balls merely roll; too fast, and they centrifuge, eliminating the crushing action.

- Grinding Media: The size, density, and material of the balls affect grinding efficiency and potential contamination.

- Feed Size: Consistently sized input material ensures uniform grinding.

- Milling Time: Longer durations yield finer powder but increase energy consumption and wear.

While ball mills are renowned for their robust construction and lower initial investment, they have inherent limitations for producing ultra-fine silica powder. These include high energy consumption, significant heat generation, potential for iron contamination from steel balls, and relatively broad particle size distribution.

Beyond the Ball Mill: The Modern Approach to Ultra-Fine Silica

For operations focused on high-value, ultra-fine silica powders (325-2500 meshes), advanced grinding technology is not just an upgrade—it’s a necessity. This is where our MW Ultrafine Grinding Mill truly shines.

The MW Series represents a significant leap forward from traditional ball milling. It’s engineered specifically for customers who need to make ultra-fine powder with higher yielding and lower energy consumption. Its newly designed grinding curves of the roller and ring enhance efficiency dramatically. In fact, with the same fineness and power, its production capacity is 40% higher than jet mills and its energy consumption is a mere 30% of theirs. Compared to a ball mill, the yield can be twice as large.

A standout feature for silica production is the mill’s adjustable fineness between 325-2500 meshes, achieved through a advanced German cage-type powder selector. This ensures precise control over your final product’s specifications. Furthermore, the absence of rolling bearings and screws in the grinding chamber eliminates worries about mechanical failure and contamination—a common concern with traditional mills.

Why Choose the MW Ultrafine Grinding Mill for Your Silica Operation?

- Superior Efficiency: Achieves higher output with significantly lower energy input compared to ball mills.

- Precision Fineness: Accurately control your product’s particle size up to 2500 mesh.

- Purity Guarantee: No metal-to-metal contact in the grinding chamber minimizes the risk of iron contamination, crucial for high-purity silica applications.

- Eco-Friendly Operation: An integrated efficient pulse dust collector and silencer ensure the entire milling system operates cleanly and quietly, meeting strict environmental standards.

While the ball mill is a proven technology for coarse grinding, the future of ultra-fine silica powder production is here. For operations aiming to enhance product quality, reduce operating costs, and boost capacity, transitioning to an advanced system like the MW Ultrafine Grinding Mill is a strategic move. It integrates crushing, grinding, and classifying into a single, efficient, and environmentally responsible package, ensuring your silica powder is not just produced, but perfected.

For operations requiring a vertical solution, our LUM Ultrafine Vertical Grinding Mill is another excellent choice, offering unique roller technology and exceptional energy savings of 30%-50% for similar applications.