How to Choose the Right Raw Mill for Your Cement Plant: A Comprehensive Guide

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

How to Choose the Right Raw Mill for Your Cement Plant: A Comprehensive Guide

Selecting the apropriate raw mill is a critical decision for any cement plant operation. It directly impacts your production capacity, energy consumption, product quality, and ultimately, your bottom line. With so many options on the market, navigating the choises can be daunting. This guide will walk you through the key factors to consider to ensure you make an informed investment.

Key Selection Criteria

The “perfect” mill doesn’t exist; the best choice is the one that perfectly matches your specific operational needs and constraints. Here are the primary factors to weigh:

- Raw Material Properties: This is the starting point. Hardness, abrasiveness, moisture content, and feed size are paramount. A mill that excels with soft limestone will struggle with highly abrasive quartzite.

- Required Capacity (tph): Your production targets will narrow down the field. Ensure the mill can handle your desired throughput without being over-sized, which leads to inefficiency.

- Desired Fineness (Blaine or mesh): The fineness of the raw meal is crucial for the kiln process. Different mills have different optimal and maximum fineness ranges.

- Energy Efficiency: Grinding is an energy-intensive process. Mills with lower specific energy consumption (kWh/t) significantly reduce operating costs. Vertical roller mills, for instance, typically offer substantial savings over traditional ball mills.

- Drying Capacity: If your raw materials have high moisture content, you need a mill with integrated drying capabilities using hot gases from the kiln or auxiliary heat source.

- Plant Footprint & Layout: Consider the available space. Vertical mills have a significantly smaller footprint compared to horizontal ball mills.

- Maintenance & Operational Costs: Evaluate the ease of maintenance, availability of spare parts, and the expected lifespan of wear parts like rollers and liners.

Types of Mills: A Quick Overview

- Ball Mills: The traditional workhorse. Reliable but generally less energy-efficient. Good for abrasive materials but with higher wear rates.

- Vertical Roller Mills (VRM): The modern standard for new plants. Offer superior energy efficiency, excellent drying capacity, and a compact design. They integrate grinding, drying, and classification in a single unit.

- Roller Presses (often with ball mill): Used for pre-grinding or in hybrid systems to significantly boost the capacity of an existing ball mill circuit.

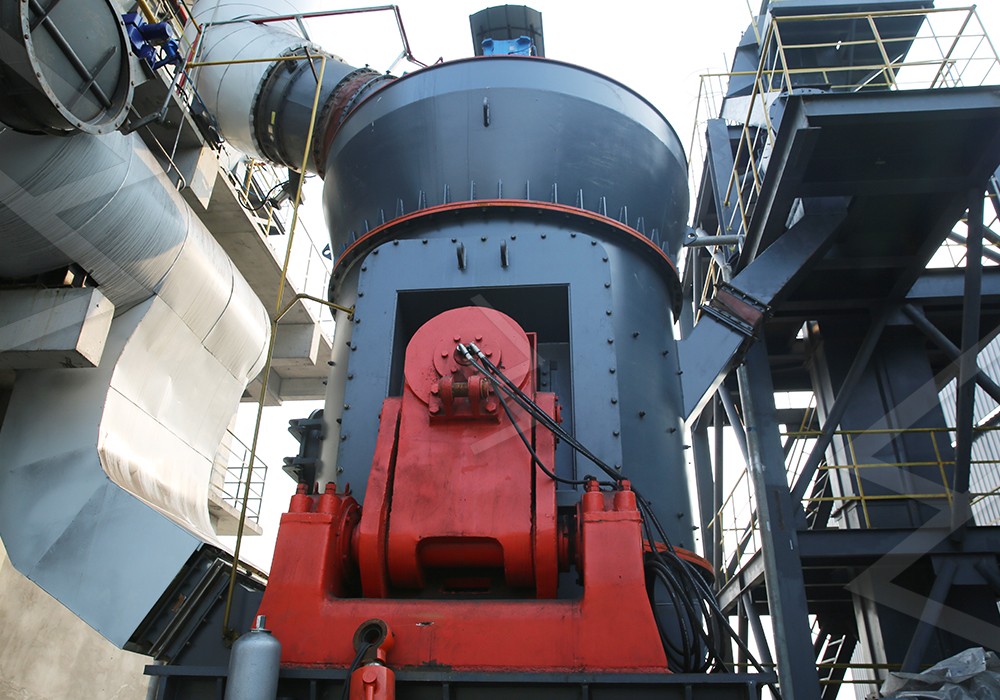

Our Recommended Solution: The LM Vertical Grinding Mill

For most modern cement plants seeking efficiency and reliability, a vertical roller mill is the superior choice. Our LM Vertical Grinding Mill is specifically engineered to meet the demanding requirements of raw material grinding.

Why the LM Vertical Mill stands out:

- High Efficiency & Low Energy Use: It integrates crushing, grinding, drying, and classifying, reducing energy consumption by 30%-40% compared to ball mill systems.

- Large Capacity: Handles input sizes up to 70mm and capacities ranging from 3 to 340 tph, making it suitable for both small and mega plants.

- Strong Drying Capability: Can utilize hot waste gases from the kiln, efficiently handling materials with high moisture content.

- Reduced Footprint: Its compact vertical design occupies about 50% of the area of a ball mill system.

- Environmental Friendly: Fully sealed system operating under negative pressure ensures no dust spillage, and its operation is notably quiet.

For operations requiring ultra-fine grinding or processing of slags, our MW Ultrafine Grinding Mill is another excellent option. It produces powder with fineness adjustable between 325-2500 meshes and is designed for higher yielding with lower energy consumption, achieving a capacity 40% higher than jet mills. Its unique design without rolling bearings or screws in the grinding chamber eliminates common failure points, ensuring worry-free, continuous 24/7 operation.

Making the Final Decision

Always partner with a reputable supplier who can provide detailed test reports based on your actual raw materials. Request case studies from similar plants and ensure robust after-sales support and spare parts availability. The right mill is a long-term partner in your plant’s profitability.

By carefully evaluating your material characteristics, production goals, and economic factors against the capabilities of different mills, you can select the optimal raw grinding system that will deliver performance and value for years to come.