Fujian 20,000 Tons Per Month Slag Micro Powder Grinding Plant Project Case

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

Fujian 20,000 Tons Per Month Slag Micro Powder Grinding Plant Project Case

In the heart of Fujian’s bustling industrial sector, a monumental project was undertaken to process a massive 20,000 tons of slag per month into valuable micro powder. This wasn’t just about waste management; it was about value creation, turning industrial byproduct into a sought-after material for cement and concrete production. The challenge was immense: achieving a consistent, high-yield output with stringent fineness requirements, all while maintaining operational efficiency and environmental compliance.

The engineering team faced several critical hurdles. The abrasive nature of slag demanded equipment with exceptional wear resistance. The required production volume was substantial, necessitating a mill with high capacity and reliability to avoid costly downtime. Furthermore, the client insisted on a solution that was energy-efficient to keep operating costs manageable and environmentally sound to meet strict local regulations.

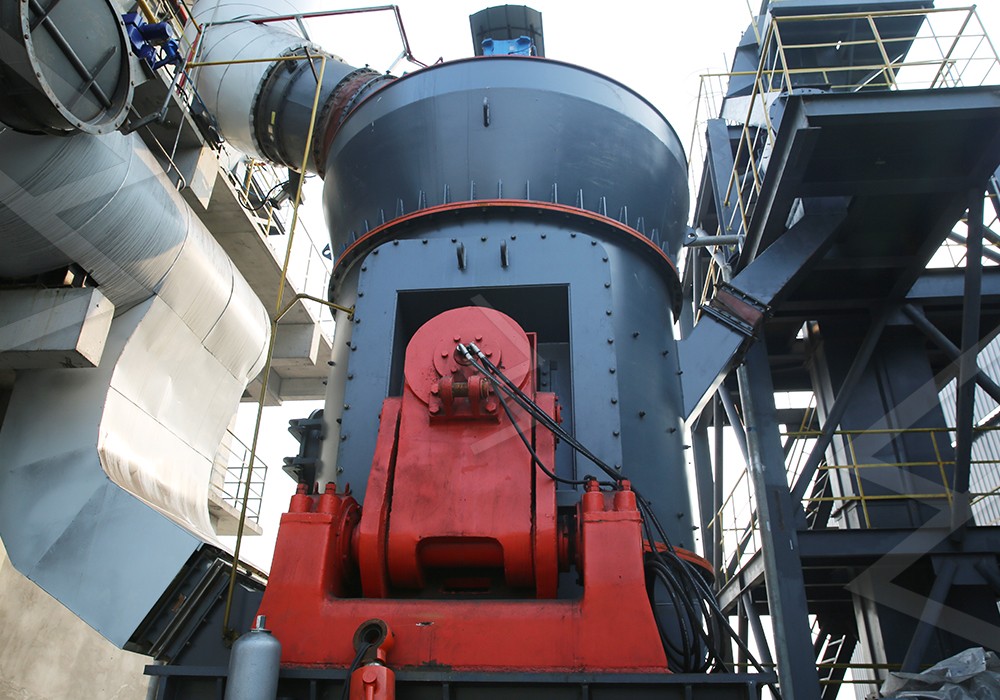

After a thorough evaluation of various technologies, the project’s core was entrusted to our LM Vertical Slag Mill. This wasn’t a random choice. The LM Vertical Slag Mill is specifically engineered for this exact purpose. Its capacity range of 7-100T/H was perfectly suited to handle the 20,000-ton monthly target. More importantly, its integrated design combines drying, grinding, powder selection, and conveying into a single, compact unit. This drastically reduced the plant’s footprint—occupying about 50% less space than a traditional ball mill system—and simplified the entire process flow.

Why the LM Vertical Slag Mill Was the Ideal Solution

The selection was vindicated by outstanding results. The mill’s unique grinding device and high-performance wear-resistant materials stood up perfectly to the slag’s abrasiveness, ensuring reliable, continuous operation and reducing maintenance frequency. Its energy efficiency was a major win; the plant realized energy savings of 30%–40% compared to the ball milling system initially considered, translating to significantly lower operating costs.

The environmental performance was another standout feature. The entire system operates under negative pressure, ensuring no dust spillage and a clean worksite. The fineness of the final powder was uniform with a high screening rate, exactly meeting the quality specifications required by the customer’s clients in the construction industry.

For projects requiring even finer powders or processing of different materials, we often recommend our MW Ultrafine Grinding Mill as a complementary or alternative solution. The MW Mill is equipment designed for customers who need to make ultra-fine powder, capable of adjustable fineness between 325-2500 meshes. It’s an excellent choice for higher value-added applications where exceptional powder quality is paramount.

Conclusion and Lasting Impact

The success of the Fujian plant stands as a testament to effective industrial waste recycling. By implementing the LM Vertical Slag Mill, the project achieved its primary goals of high volume production, operational reliability, and cost-effectiveness. The client now profitably converts a waste material into a commercial product, contributing to a more circular economy. This case study serves as a powerful blueprint for other regions and industries looking to implement large-scale, sustainable slag processing operations.