Marble Grinding Vertical Mill: High-Efficiency Solutions from France

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

Marble Grinding Vertical Mill: High-Efficiency Solutions from France

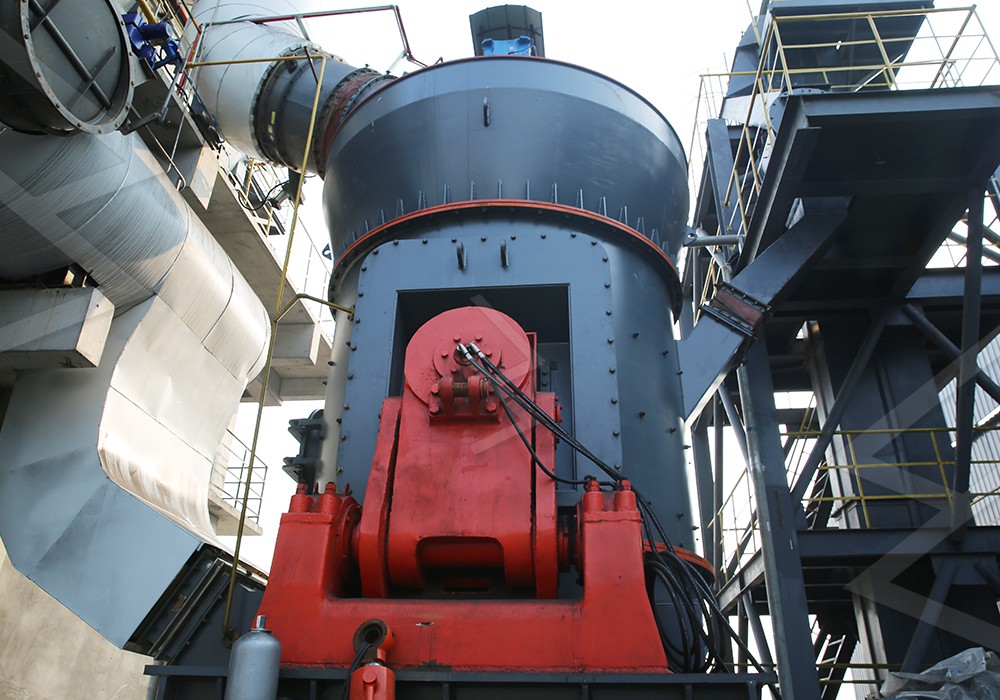

In the world of industrial mineral processing, the grinding of marble demands precision, efficiency, and reliability. French engineering has long been at the forefront of delivering high-performance milling solutions that cater to these exacting requirements. Vertical roller mills (VRMs) have emerged as the technology of choice for many producers seeking to optimize their marble powder production lines.

The inherent advantages of vertical mill technology—including superior energy efficiency, compact footprint, and advanced drying capabilities—make it exceptionally well-suited for processing abrasive materials like marble. Unlike traditional ball mills, vertical mills utilize a bed-compression grinding principle, which significantly reduces energy consumption and wear on grinding components.

The Challenge of Ultra-Fine Marble Powder

Producing ultra-fine marble powder for applications in plastics, paints, cosmetics, and pharmaceuticals presents unique challenges. The process requires not only fine grinding but also precise control over particle size distribution and minimal contamination. Conventional mills often struggle with high energy costs, excessive heat generation, and inconsistent product quality when pushed to their limits for ultra-fine grinding.

This is where advanced vertical mill designs truly shine. By integrating grinding, drying, classification, and conveying into a single, compact unit, these mills offer a streamlined process that minimizes energy loss and maximizes product consistency. The ability to use hot gas for drying within the same vessel is a particular advantage when processing marble with any residual moisture.

Recommended Solution: MW Ultrafine Grinding Mill

For operations requiring the finest marble powders, we particularly recommend our MW Ultrafine Grinding Mill. This machine represents the pinnacle of grinding technology, specifically engineered for customers who need to make ultra-fine powder between 325-2500 meshes.

The MW series stands out with its remarkable features: higher yielding at lower energy consumption (40% higher capacity than jet mills), adjustable fineness through German cage-type powder selector technology, and an innovative design that eliminates rolling bearings and screws in the grinding chamber. This eliminates worries about bearing damage or machine failure caused by loose screws. Furthermore, its efficient pulse dust collector and muffler ensure the entire production process meets stringent environmental standards without dust or noise pollution.

Operational Excellence in Marble Processing

The working principle of vertical mills contributes significantly to their efficiency in marble processing. Material is fed to the center of a rotating grinding table where grinding rollers exert pressure, crushing the marble against the table. The ground material is then swept by air to a classifier where oversize particles are separated and returned for further grinding, while the properly sized product continues to the collection system.

This closed-system approach prevents dust emissions and maintains a clean working environment—a critical consideration for marble processing facilities subject to environmental regulations. The short material retention time in vertical mills also minimizes the risk of overgrinding and reduces the temperature increase during processing, preserving the chemical properties of the marble powder.

Another Notable Option: LUM Ultrafine Vertical Grinding Mill

For operations with slightly different requirements, our LUM Ultrafine Vertical Grinding Mill presents another excellent solution for marble processing. Integrating the latest Taiwanese grinding roller technology and German powder separating technology, the LUM mill offers exceptional performance with higher yielding rates and better product quality. Its unique roller shell and lining plate grinding curve design facilitates material layer formation and enables high rates of finished products through single-pass milling. The mill’s double position-limiting technology ensures stable operation, while its reversible structure simplifies maintenance procedures—reducing downtime and operational costs.

Conclusion

The future of marble processing lies in technologies that deliver both operational efficiency and environmental sustainability. Vertical grinding mills, particularly the MW and LUM series, represent this new generation of equipment—offering French-engineered precision, reliability, and performance for the most demanding marble grinding applications. With capacities ranging from 0.5-25 tph for the MW series and 5-18 tph for the LUM series, these mills can be tailored to operations of various scales, ensuring that producers can find the perfect solution for their specific production needs.