Carbonized Blast Furnace Slag Vertical Roller Mill Supplier – Grinding Mill Manufacturer

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

Advanced Grinding Solutions for Carbonized Blast Furnace Slag

In the world of industrial milling, processing carbonized blast furnace slag presents unique challenges that demand robust, efficient, and precise equipment. As a leading grinding mill manufacturer, we understand the critical importance of selecting the right machinery to transform this industrial byproduct into valuable, high-quality powder for various applications, including cement production, concrete additives, and construction materials.

The Challenge of Slag Grinding

Carbonized blast furnace slag is known for its abrasive nature and variable composition, which can wreak havoc on conventional grinding systems. Traditional ball mills often struggle with high energy consumption, excessive wear on components, and inconsistent product quality. This is where vertical roller mills specifically designed for such materials make a significant difference.

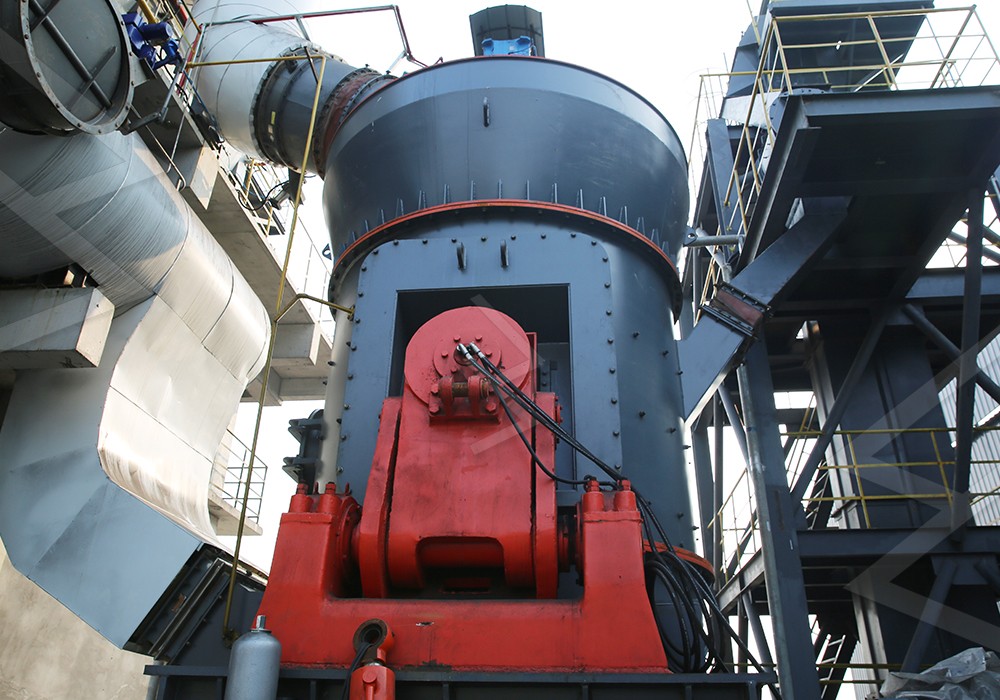

Our Recommended Solution: LM Vertical Slag Mill

After decades of research and field testing, we’ve developed the LM Vertical Slag Mill specifically for handling industrial waste materials like carbonized blast furnace slag. This specialized equipment integrates drying, grinding, powder selection, and conveying in a single, compact system.

The LM Vertical Slag Mill offers remarkable advantages for slag processing:

- 50% reduced footprint compared to ball milling systems

- 30-40% lower energy consumption

- Integrated drying capability for moist materials

- High wear-resistant components designed for abrasive materials

- Consistent product quality with uniform fineness

Technical Superiority in Slag Processing

What sets our vertical slag mill apart is its unique grinding device that achieves the integration of grinding and powder selection. The mill operates on a negative-pressure air-sweep principle, where hot air enters the mill body simultaneously as material is fed to the grinding table. The grinding rollers exert tremendous pressure on the slag material, crushing it efficiently while the airflow carries the fine particles to the separator.

Another Excellent Option: MW Ultrafine Grinding Mill

For operations requiring ultra-fine slag powder, our MW Ultrafine Grinding Mill presents an outstanding alternative. This advanced machine handles input sizes up to 20mm with capacities ranging from 0.5-25 tph, making it suitable for various production scales.

The MW Ultrafine Grinding Mill features several innovative technologies:

- Higher yielding with 40% increased capacity compared to jet mills

- Adjustable fineness between 325-2500 meshes

- No rolling bearings or screws in the grinding chamber

- Efficient pulse dust collector for eco-friendly operation

- External lubrication system allowing 24-hour continuous operation

This mill particularly excels when producing superfine slag powder for high-value applications where precise particle size distribution is critical.

Why Choose Our Grinding Solutions?

Our company brings decades of expertise in designing and manufacturing grinding equipment specifically for challenging materials like carbonized blast furnace slag. We understand that downtime is costly, which is why our mills are built with durability and maintainability in mind.

All our grinding mills feature digitalized processing for higher precision, with tens of lines of numerical controlling machine tools ensuring exact specifications. From steel plate cutting and bending to planing, milling, and paint spraying, every operation is controlled numerically for consistent quality.

Comprehensive Support and Service

We stand behind every machine we produce, offering complete technical services and original spare parts to ensure worry-free operation. Our business covers both production and sales, allowing us to maintain quality control throughout the entire process and provide direct support to our customers.

Whether you’re processing carbonized blast furnace slag for cement production, concrete enhancement, or other industrial applications, our vertical roller mills offer the reliability, efficiency, and product quality necessary for competitive operation in today’s market.

Contact our technical team today to discuss your specific slag grinding requirements and discover how our specialized milling solutions can enhance your operation’s productivity and profitability.