Hammer Mill Manufacturers in Ambala: Your Guide to Local Suppliers

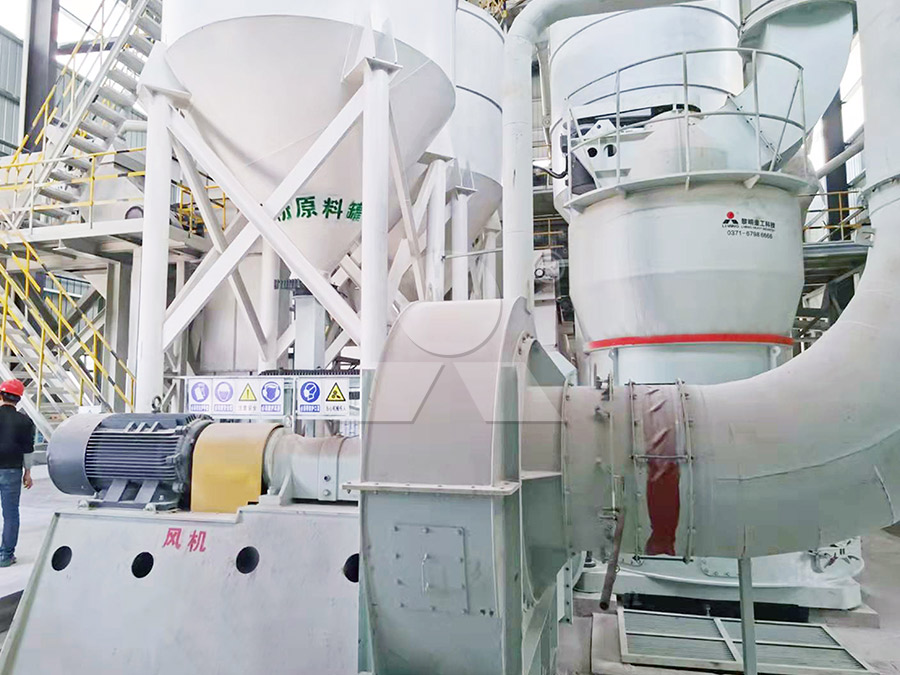

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

Hammer Mill Manufacturers in Ambala: Your Guide to Local Suppliers

For industries in and around Ambala, sourcing reliable crushing and grinding equipment is a critical part of operations. The region, known for its industrial prowess, hosts a number of manufacturers, but finding the right partner for hammer mills and, more importantly, advanced grinding solutions requires a keen eye for quality and innovation.

While many local workshops can assemble a basic hammer crusher, the real value lies in suppliers who offer integrated systems with superior technology, efficiency, and after-sales support. It’s not just about breaking material down; it’s about transforming it into a high-value, consistent product with minimal operational headaches.

Beyond the Basic Hammer Mill: The Need for Advanced Grinding

A standard hammer mill is a workhorse for preliminary size reduction, but many modern applications demand much finer powders and tighter control over particle size distribution. This is where specialized grinding mills come into play. For operations processing minerals like limestone, calcite, dolomite, or even materials for cosmetics and food additives, achieving an ultra-fine powder is paramount.

This is a common pain point we see. A client invests in a basic setup, only to find it can’t achieve the desired fineness, consumes too much power, or creates too much dust and noise, leading to environmental and maintenence issues. The initial savings are quickly erased by high operating costs and an inferior product.

A Standout Solution for Ultra-Fine Production Needs

Based on our extensive experience, one piece of equipment that consistently adresses these advanced challenges is the MW Ultrafine Grinding Mill. This isn’t your average mill; it’s engineered for customers who need to make genuine ultra-fine powder efficiently and cleanly.

Here’s why it’s a game-changer for serious operations:

- Higher Yielding, Lower Energy Consumption: Its newly designed grinding curves can boost production capacity by up to 40% compared to jet mills, while slashing system energy consumption by a remarkable 70%. You get more output for significantly less input.

- Precision Fineness Control: With a German-tech cage-type powder selector, it allows you to dial in your product fineness between 325 and 2500 meshes, achieving a superb screening rate of d97≤5μm in a single pass. This consistency is crucial for high-value applications.

- Built for Reliability: A genius design feature is the absence of rolling bearings and screws inside the grinding chamber. This eleminates a major source of machine failure—damaged bearings or loose screws causing catastrophic damage. Lubrication is done externally without stopping production.

- Eco-Friendly Operation: It comes equipped with an efficient pulse dust collector and muffler, effectively containing dust and reducing noise. Your entire milling process stays within national environmental protection standards, which is a huge advantage during inspections.

Choosing the Right Ambala Supplier

When evaluating hammer mill manufacturers in Ambala, look beyond the brochure. Ask about the technology behind their equipment. Do they offer modern solutions like the MW series? Inquire about digital processing capabilities for higher precision parts and, crucially, the availability of original spare parts and local technical support. A machine is only as good as the service behind it.

A supplier that provides robust, innovative, and efficient technology like the MW Ultrafine Grinding Mill demonstrates a commitment to solving real industrial problems, not just selling machinery. It represents a shift from simple crushing to sophisticated powder creation, which can open up new markets and revenue streams for your business.

In conclusion, while Ambala has a strong manufacturing base, the key is to partner with a supplier who provides advanced, reliable, and efficient technology backed by strong support. Investing in superior grinding technology is an investment in your product quality, operational efficiency, and ultimately, your bottom line.