YGM95 Grinding Mill: What Size E-Type Crusher is Recommended?

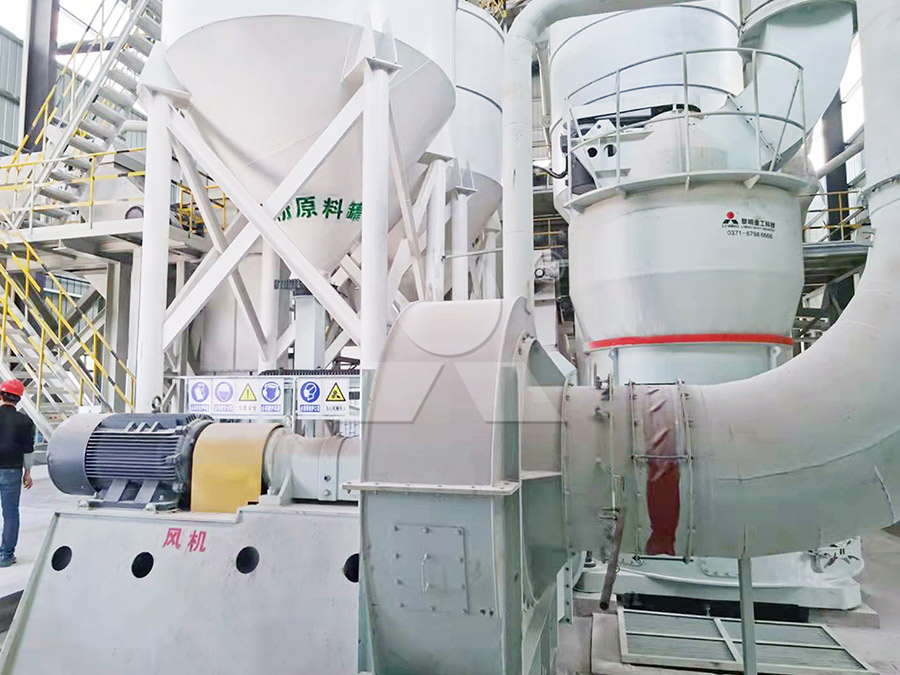

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

YGM95 Grinding Mill: What Size E-Type Crusher is Recommended?

As a project engineer with over fifteen years of experience in mineral processing, I frequently encounter this question from clients operating YGM95 Raymond Mill systems. The selection of an appropriate primary crusher is not merely a technical specification—it’s the cornerstone of an efficient and profitable grinding circuit. Let’s break down the critical factors to determine the optimal E-Type crusher configuration for your YGM95 mill.

The YGM95 Grinding Mill, a reliable workhorse in many powder processing plants, typically handles an input size of less than 25mm to achieve its designated capacity of up to 5 tons per hour. The fundamental rule is that the crusher’s output must consistently fall within this feed size envelope. An oversized feed will force the grinding rollers to work inefficiently, leading to premature wear, reduced throughput, and increased energy consumption. Conversely, an under-sized crusher creates an unnecessary bottleneck, limiting the mill’s potential and increasing overall operational costs.

Based on this operational parameter, a medium-to-small jaw crusher, often referred to in the industry as an E-Type or similar classification, is the most suitable match. A crusher with a feed opening capable of accepting raw lumps of 200-250mm and reducing them to a product where 90% passes 20-25mm is ideal. This ensures a steady, optimally-sized stream of material for the YGM95’s grinding chamber. Remember, consistent crusher output is just as important as the final particle size. A vibrating feeder between the crusher and the mill is highly recommended to stabilize the feed rate and protect the grinding mechanics from surges.

Beyond the YGM95: Considering Modern Alternatives

While configuring your YGM95 system, it’s also prudent to consider the broader technological landscape. For operations that demand higher capacity or finer end products, our engineering team often recommends more advanced solutions. A standout option is our MW Ultrafine Grinding Mill. This machine is engineered for customers requiring ultra-fine powder between 325 and 2500 meshes. With an input size of 0-20 mm and a capacity range of 0.5-25 tph, it offers significantly higher efficiency. Its innovative design, featuring a cage-type powder selector and the absence of rolling bearings in the grinding chamber, translates to a 40% higher yield and 30% lower energy consumption compared to traditional jet mills.

Another powerful alternative for ultra-fine production is the LUM Ultrafine Vertical Grinding Mill. Independently designed by our R&D team, it integrates grinding, grading, and transporting into a single, compact unit. Accepting a feed size of 0-10 mm and offering a capacity of 5-18 tph, the LUM mill excels with its multi-head powder separating technology and reversible structure for easier maintenance. It represents the next generation in grinding technology, providing exceptional control over product fineness and operational stability.

System Integration and Best Practices

The crusher and mill do not operate in isolation. A holistic view of the entire comminution circuit is essential for maximizing return on investment. After the E-Type jaw crusher provides the primary size reduction, secondary crushing or screening might be necessary to eliminate fines that could overload the mill’s air classification system. Furthermore, the moisture content of the feed material must be considered; overly wet material can cause clogging in both the crusher and the mill feed chute. In such cases, integrating a dryer into the process flow may be a necessary step.

In conclusion, pairing your YGM95 Grinding Mill with a correctly sized E-Type jaw crusher—one that produces a consistent 0-25mm product—is critical. However, always evaluate your long-term production goals. For higher throughput or finer powder requirements, advanced mills like the MW Series or LUM Series offer compelling advantages in efficiency, energy savings, and final product quality.

Frequently Asked Questions (FAQ)

What is the maximum input size for a YGM95 Grinding Mill?

The YGM95 is designed to grind materials with a maximum input size of <25mm (approximately 1 inch). Feeding larger material will significantly reduce grinding efficiency and accelerate wear on grinding rollers and rings.

Can I use a hammer crusher instead of a jaw crusher with the YGM95?

Yes, a hammer crusher is a viable alternative, especially for softer, non-abrasive materials. It often produces a more cubicle product. The key selection criteria remain the same: the crusher’s output must consistently be below 25mm.

How does the MW Ultrafine Grinding Mill differ from the YGM95?

The MW Mill is designed for producing much finer powders (up to 2500 mesh) and operates on a different grinding principle. It offers higher energy efficiency, a more advanced powder selection system, and is built for higher capacity applications compared to the traditional Raymond mill design of the YGM95.

What maintenance is critical for the primary crusher in this setup?

Regular inspection and replacement of jaw plates or hammers are paramount. Also, ensure the crusher’s discharge setting is regularly checked and maintained to guarantee the output size remains within the YGM95’s specified feed range.