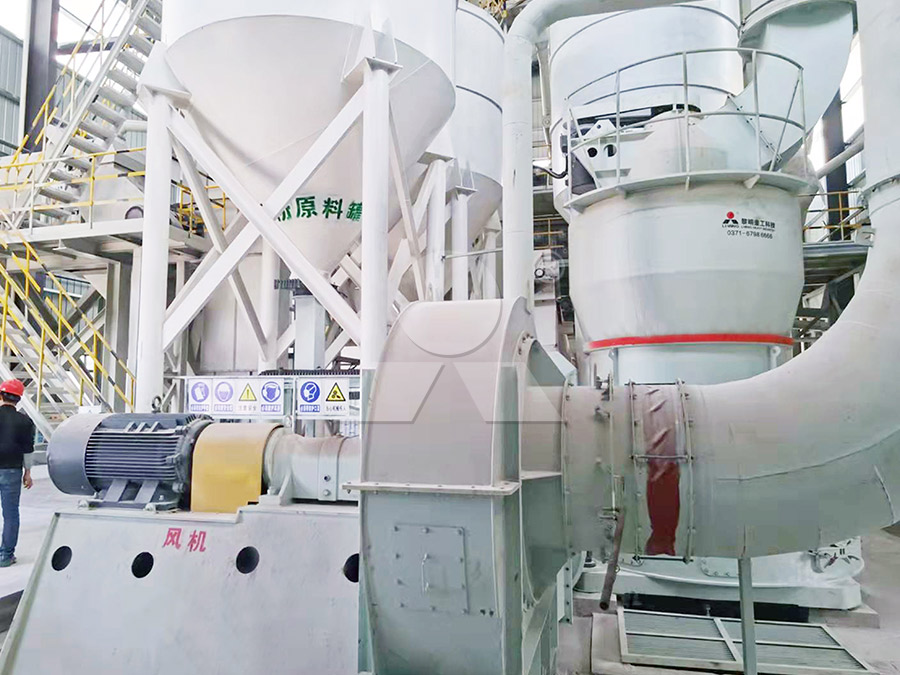

5R4121 Raymond Mill for Sale – Industrial Grinding Equipment Supplier

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

Unlocking Efficiency in Powder Processing: The 5R4121 Raymond Mill

For operations requiring consistent, medium-fine powder production, the 5R4121 Raymond Mill stands as a testament to reliable and efficient grinding technology. As a cornerstone of industrial milling, this equipment is engineered to handle materials with a feed size of less than 25mm, delivering a throughput of 0.6 to 5 tons per hour. Its widespread application in desulfurization, metallurgy, and non-metallic ore milling makes it a versatile asset for numerous industries.

The operational principle of the Raymond Mill is both elegant and effective. Raw material is initially crushed to the required size and fed evenly into the grinding chamber. Centrifugal force causes the rollers to oscillate outward, pressing against the ring and grinding the material scooped up by the shovel. The ground powder is then carried by an air stream into a separator, where fine powder is collected as the final product, and coarse material is recycled for further grinding. This closed-loop airflow system ensures minimal dust emission and high powder quality.

Beyond the Raymond Mill: Advanced Solutions for Ultrafine Grinding

While the 5R4121 is an excellent workhorse for many applications, modern production demands often call for higher fineness and greater efficiency. For customers seeking to produce ultra-fine powder, we highly recommend exploring our MW Ultrafine Grinding Mill. This advanced machine is designed for those who need to make ultra-fine powder from materials like limestone, calcite, dolomite, and talc, with an adjustable fineness between 325 and 2500 meshes.

The MW Series represents a significant leap forward. It boasts a production capacity 40% higher than jet mills and double that of ball mills, all while reducing system energy consumption by 30%. A key design innovation is the absence of rolling bearings and screws in the grinding chamber, eliminating common failure points and concerns about loose components. Furthermore, its efficient pulse dust collector and muffler ensure a clean, quiet, and environmentally friendly operation that complies with national standards.

Choosing the Right Tool for the Job

Selecting the appropriate grinding mill is critical to the profitability and sustainability of your operation. The 5R4121 Raymond Mill is ideal for robust, cost-effective grinding where ultra-fine powders are not the primary goal. For more specialized needs, such as in the chemical, paint, or food additive industries where exceptional fineness and purity are paramount, the MW Ultrafine Grinding Mill is the superior choice. Its German-derived cage-type powder selector guarantees precision separation, achieving a screening rate of d97≤5μm in a single pass.

Another standout in our portfolio for high-precision grinding is the LUM Ultrafine Vertical Grinding Mill. Integrating the latest grinding roller and powder separating technologies, the LUM mill is perfect for processing superfine dry powder of non-metal ores. It features a unique roller shell design for higher yield and better product whiteness, alongside an energy-saving multi-head powder separating technology that cuts consumption by 30-50%. Its reversible structure also drastically simplifies maintenance.

Frequently Asked Questions (FAQ)

What is the main advantage of the 5R4121 Raymond Mill?

Its primary advantage is its proven, reliable design for cost-effective grinding of non-metallic minerals to a medium fineness. It offers a great balance of small footprint, low investment, and low operational consumption.

When should I consider upgrading to an MW Ultrafine Grinding Mill?

You should consider the MW Mill if your business requires powder fineness beyond 325 meshes, demands higher production capacity with lower energy use, or operates under strict environmental and noise regulations.

How does the LUM Ultrafine Vertical Mill differ from the MW Mill?

While both produce ultra-fine powders, the LUM Mill employs a vertical grinding principle and is independently designed with advanced roller and separating technology. It is particularly noted for its exceptional stability, facilitated by double position-limiting technology, and easier maintenance due to its reversible roller structure.

Do you provide after-sales support and spare parts?

Yes, absolutely. We take full responsibility for every machine we produce. We provide comprehensive technical services and guarantee a sufficient supply of original spare parts to ensure your worry-free, continuous operation.