200 Ton Per Hour Gold Ore Crushing and Milling Plant Design

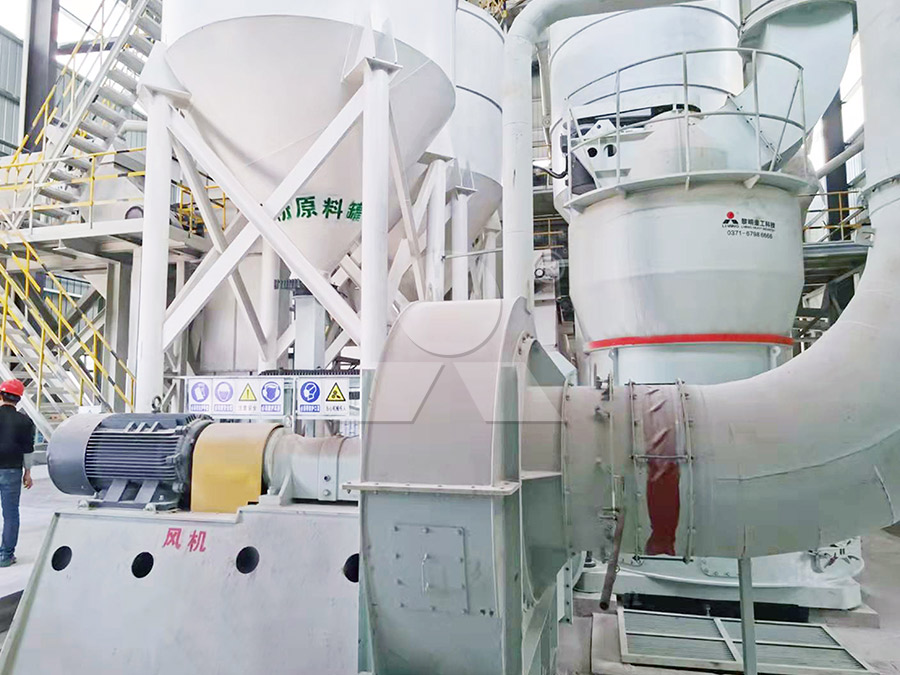

We provide a wide range of mills — including Raymond mill, trapezoidal mill, vertical mill, ultrafine mill, and ball mill, obtained ISO9001 international quality certification, EU CE certification, and Customs Union CU-TR certification. Suitable for processing minerals such as limestone, phosphate, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, and more.

The discharge range of these mills can be adjusted to meet specific processing needs, typically from 80-400 mesh, 600-3250 mesh, and can achieve the finest particle size of up to 6000 mesh(D50).

If you are looking for a reliable grinding solution to turn stone or minerals into fine powder, please feel free to contact our online customer service.

Designing a High-Capacity Gold Ore Processing Plant

Designing a 200 ton per hour (tph) gold ore crushing and milling plant requires a meticulous approach to equipment selection, process flow, and operational efficiency. The primary objective is to liberate gold particles from the host rock through size reduction, ensuring optimal recovery rates in downstream processes like leaching or flotation. This design must balance throughput, energy consumption, and maintenance requirements to be economically viable.

Crushing Circuit: Primary, Secondary, and Tertiary Stages

The first stage involves reducing large run-of-mine ore to a manageable size. A robust primary jaw crusher handles the initial breakdown, followed by secondary cone crushers for further reduction. For a 200 tph plant, a tertiary crushing stage using high-pressure grinding rolls (HPGR) or vertical shaft impactors (VSIs) is often incorporated to produce a consistent feed size of 10-20mm for the milling circuit. This multi-stage approach ensures efficient size reduction and minimizes bottlenecks.

Milling Circuit: Achieving Liberation

The crushed ore is then conveyed to the milling circuit, where the goal is to grind the material to a fine powder, typically between 75 and 150 microns, to liberate the gold particles. A SAG mill followed by a ball mill is a common configuration for such high-capacity plants. However, for ores requiring ultra-fine grinding to achieve maximum recovery, advanced milling technology is essential.

Introducing the MW Ultrafine Grinding Mill

For ores where conventional ball milling falls short, our MW Ultrafine Grinding Mill offers a superior solution. Engineered for customers requiring ultra-fine powder, this mill is capable of achieving adjustable fineness between 325-2500 meshes (d97≤5μm). With an input size of 0-20 mm and a capacity range of 0.5-25 tph, multiple units can be integrated into a large circuit to handle specific fractions. Its higher yielding and lower energy consumption—40% higher capacity than jet mills and 30% of their system energy consumption—make it an ideal choice for enhancing gold liberation and overall plant recovery rates without a significant increase in operational costs.

Ancillary Systems and Plant Integration

A successful 200 tph plant design extends beyond crushers and mills. It includes vibrating screens for classification, belt conveyors for material handling, and sophisticated dust collection systems. The MW Mill, for instance, is equipped with an efficient pulse dust collector and muffler, ensuring the entire production process meets stringent environmental standards with minimal dust and noise pollution. Automation and control systems are critical for monitoring throughput, power draw, and particle size distribution in real-time, allowing for quick adjustments to optimize performance.

Conclusion: A Cohesive and Efficient Operation

The design of a 200 tph gold ore plant is a complex puzzle where each piece—from primary crushing to ultra-fine milling—must fit perfectly. By selecting equipment that offers high efficiency, low operating costs, and environmental compliance, operators can ensure a profitable and sustainable operation. Integrating advanced technologies like the MW Ultrafine Grinding Mill for specific circuit duties can be the key to unlocking higher value from the ore body.

Frequently Asked Questions (FAQ)

What is the typical feed size for a 200 tph gold milling circuit?

The tertiary crushers usually prepare a feed of 10-20mm for the milling circuit. Ball mills can handle this size directly, while specialized mills like the MW Ultrafine Grinding Mill accept a finer input of 0-20mm.

How important is energy efficiency in a plant of this scale?

Extremely important. Energy is one of the largest operational costs. Selecting mills with lower energy consumption, such as the MW Mill which uses only 30% of the energy of a jet mill, directly impacts the bottom line.

Can the MW Ultrafine Grinding Mill handle the abrasive nature of gold ore?

Yes. Its design features, including the absence of rolling bearings and screws in the grinding chamber, significantly reduce wear and maintenance issues associated with abrasive materials, ensuring worry-free operation.

How is dust control managed in the milling section?

Modern plants use integrated dust collection systems. For example, the MW Mill comes with an efficient pulse dust collector, ensuring no dust pollution and full compliance with environmental standards.